TH-FLC500SL JPT【FOB】High-Precision 500W Nanosecond Pulse Laser Cleaner - Eco-Friendly Surface Decontamination Tool for Manufacturing

Baiketech TH-FLC500SL 500W JPT Trolley Box Fiber Laser Cleaning Machine! |

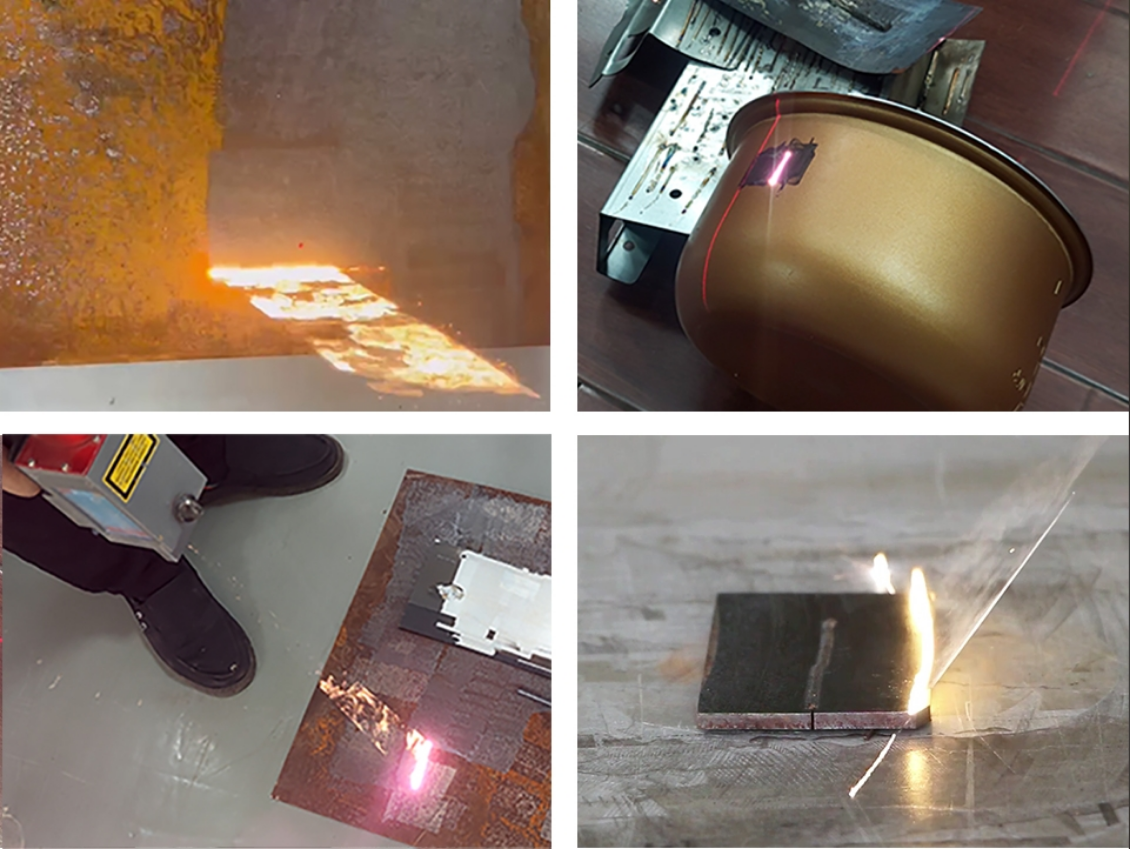

| Laser cleaning is a new technology based on the interaction between laser andsubstance, which can achieve the effect of removing surface pollution and attach.ments. Compared twith traditional cleaning methods, laser cleaning has theadvantages of non-contact,no damage to the substrate, accurate cleaning,green"environmental protection and online, especially suitable for high-speeoonline cleaning in designated areas. |

|

|

| Key Features |

| 1. Non-contact cleaning, no damage to the parts matrix; 2. Accurate cleaning, can achieve precise position, precise size selective cleaning; 3. Do not need any chemical cleaning solution, no consumables, safe and environmentaprotection; 4. Simple operation, can be hand-held or with the robot to achieve automatic cleaning; 5. Ergonomic design, operation labor intensity is greatly reduced; 6. High cleaning effciency, saving time; 7. Laser cleaning system is stable, almost no maintenance. |

|

| Technical Parameters |

| Operating environments | |

| Content | TH-FLC500SL |

| Supply voltage | Single phase220V±10%、50/60Hz AC |

| Power consumption | <1500W |

| Working environment temperature | 5℃~40℃ |

| Working environment humidity | ≤80% |

| Optical parameters | |

| Average laser power | ≥500W |

| Power instability | <5% |

| Laser Working Mode | Pulse |

| Pulse width | 10-500ns |

| Maximum monopulse energy | 1.5mJ/5mJ/ |

| Power regulation range(%) | 0-100( Gradient Adjustable) |

| Repeat frequency(kHz) | 1-3000(Gradient Adjustable) |

| Fiber length | 3m |

| Cooling mode | Air cooling |

| Cleaning Head Parameters | |

| Scan range (length * width) | 0mm~100 mm, continuously adjustable; supporting 8 scanning modes |

| Scanning frequency | The maximum is not less than 300Hz |

| Field mirror focal length(mm) | 160mm( Optional 210mm/254mm/330mm/420mm) |

| Depth of focus | About 5 mm |

| Mechanical parameters | |

| Machine size(Length,width and height) | About500mm×240mm×510mm |

| Machine Weight | About 25Kg |

| Cleaning head weight | <0.75Kg |

| Mode of operation | Handheld/automated |

| Product Analysis |

| Our laser coating removal solution removes paint and other hazardous coatings from targeted areas of vehicles and parts. We use low-, mid-, or high-powered technology to clean equipment and vehicles that require small area localized cleaning for modification, corrosion control, or other subsequent tasks. Whether the area is inches or a few feet, our precision laser cleaning solutions work well on unique geometries and three-dimensional shapes — and both the cleaning and cleanup are all done in one step with the handheld optic. Through the process of laser ablation, the coatings are removed to the bare metal without impacting or damaging the substrate. |

|

|

|

|

Cleaning HeadErgonomic design, operation labor intensity is greatly reduced; Easy to operate, can be hand-held automatic cleaning

|

Laser Cleaning SystemOperation interface provides 8 cleaning modes: linear mode, rectangular mode rectangular mode2, circular mode, sinemode,spiral mode,free mode, ring mode.

|

|

|

Heat Dissipation DesignUnique structural design ensures instant response and matching between the heat dissipation capacity and heat generation of the laser.

|

Controlling PanelEquipped with an intelligent operating panel, different buttons and simple interface, the machine is easy to operate.

|

| Application |

| More Choices |

| We also have continuous laser cleaning machines, Pulse Fiber laser cleaning machines, and trolley case laser cleaning machines. There is always one machine that meets your needs. |

|

|

| Company Profile |

|

Wuhan Baike Times Laser Technology Co., Ltd. was founded in 2014 as a professional supplier of laser machine, located in Optical Valley of China, has gathered the best R&D, production and marketing teams in the domestic laser industry. More than 100 kinds of industrial laser products, including pneumatic marking machine, laser marking machine, laser welding machine, laser cutting machine, developed by the company's technical team, have been widely used in 3C electronics, semi conductor, new energy (including photovoltaic), metal processing, automobile manufacturing, electric power, textile machinery, fashion FMCG, medical devices, instruments and meters, food processing and other industries. The product quality and service have been highly praised by customers internationally. We have achieved strategic cooperation with dozens of domestic top 500 manufacturing enterprises. We've been dedicated to provide our customers with the highest quality, the best cost performance, the most suitable laser equipment. lf you have any needs, please call/mail us directly. All you need to do is just tell uswhat you need, wel provide the most professional services. |

| FAQs |

|

1. What are the advantages of using a Pulsed Laser Cleaning Machine over traditional cleaning methods? Answer: Advantages include improved cleaning effciency, precision targeting of contaminants without harming the underlying material, no requirement for chemical cleaning agents, and reduced long-term maintenance costs. 2. Can Pulsed Laser Cleaning Machines be used on any type of material?

Answer: While pulsed laser cleaning works on a wide range of materials, it should be used with caution on certain substrates that may be sensitive to heat or light, it's important to check the compatibility with your specific material first.

3. What are the precautions during the use of the cleaning machine?

Answer: Electrical power supply of the cleaning equipment is 220V 50Hz AC power supply; About 2m of ventilation must be left around the equipment. In the course of operation, labor protective equipment should be worn according to regulations, and protective glasses must be worn near the laser beam; Do not place flammable and explosive items near the cleaning machine! Such items should avoid direct or reflective laser.

4. How long do Pulsed Laser Cleaning Machines last?

Answer: With proper care and routine maintenance, pulsed laser cleaning machines can last for many years. The lifespan also depends on the frequency and intensity of their use.

5. How about the Warranty?

Answer: We offer a one-year warranty(not include consumables) except for human damage.

6. How long is your delivery time?

Answer: Generally it is 5-10 days if the goods are in stock. Or 15-20 days if the goods are not in stock, it is according to quantity.

7. How can we guarantee quality?

Answer:Always a pre-production sample before mass production; Always final inspection before shipment;

8. What can you buy from us?

Answer: Laser Cutting Machine, Laser Welding Machine, Laser Cleaning Machine , Laser Source, Laser Machine consumables.

it's one year. And don't be worry ,even after the warranty, there will be a special engineer to help.

9. Why should you buy from us not from other suppliers?

Answer:We have 10+ years experience in laser cutting business and sheet metal fabrication industry, sourcing the best value chain of laser cutting machine and sheet metal fabrication machineries for the global fabricators is our target.

|