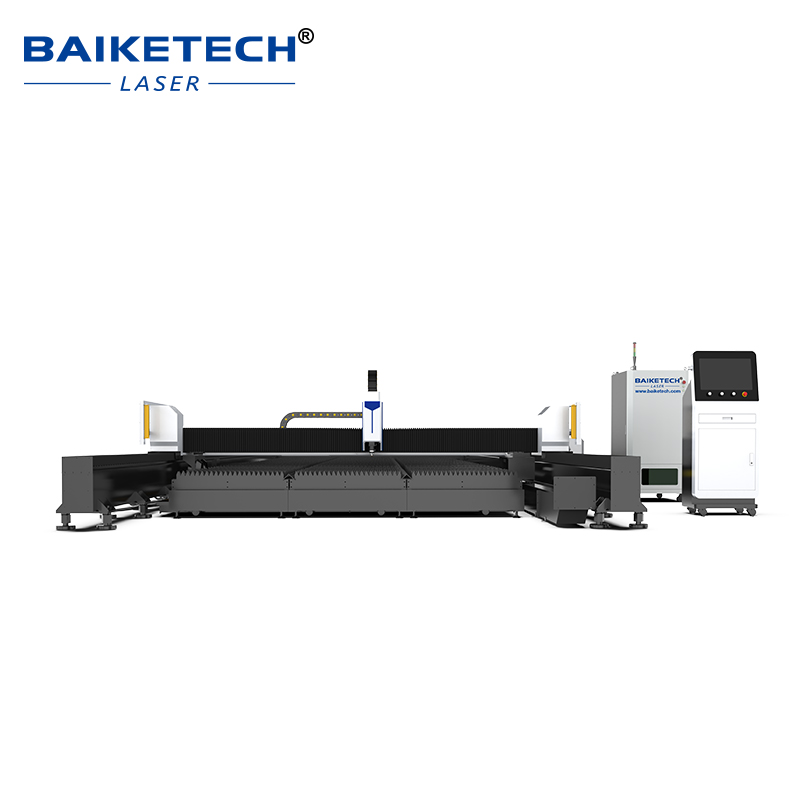

TH-GR3200-12 12KW【FOB】Large Platform Cutting Machine

Baike Tech TH-GR3200-12 6000W/12000W/20000W/30000W/40000W【FOB】Metal Sheet Fiber Laser Cutting Machine with Single Platform |

| Description: |

| Key Features: |

|

1. Ultra-large platform design: The ultra-large platform laser cutting machine has an ultra-large cutting platform that can accommodate and process large metal sheets. This design is not only suitable for large-scale production needs, but also ensures high efficiency and precision during processing. 2. High-precision cutting technology: The use of advanced laser cutting technology ensures the smoothness and precision of the cutting edge. Even when processing complex graphics or thick plate materials, it can maintain high-quality cutting effects to meet the needs of precision manufacturing. 3. Powerful cutting ability: Equipped with high-power lasers, it has powerful cutting capabilities and can easily penetrate metal materials of various thicknesses. Whether it is thin or thick plates, it can achieve fast and efficient cutting. 4 Intelligent control system: Integrated intelligent control system supports automated programming and operation. Users can input cutting parameters through a simple interface to achieve fast cutting of complex graphics. At the same time, the system also has automatic optimization functions to improve cutting efficiency and precision. 5. Durability and stability: The use of high-quality materials and advanced manufacturing processes ensures the durability and stability of the equipment. Even under long-term continuous work, it can maintain stable cutting performance and precision. 6. Flexible customization service: |

| Application: |

|

Laser cutting machines are suitable for almost all industrial manufacturing fields, such as vehicle manufacturing, aerospace, electronic appliances, kitchenware manufacturing, fitness equipment, advertising and metal processing. |

| Parameters of Machine: |

| Name | Quantity | Brand |

| Laser | 1 set | Fiber Laser |

| Laser Power | 1 set | 1500W |

| Special laser cutting head | 1 set | RayTools auto focus |

| Machine tool bed | 1 PC | BAIKE Tech |

| XY axis precision rack | 1 set | T-win |

| XY axis precision guide rail | 1 set | Taiwan Shangyin HIWIN |

| X, Y axis servo motor and driver | 3 sets | INOVANCE |

| Z-axis servo motor and driver | 1 set | INOVANCE |

| reducer | matching | Federler reducer |

| Major electrical component | matching | Schneider |

| Control cabinet | 1 set | BAIKE Tech |

| Machine tool accessories | matching | BAIKE Tech |

| Numerical control system | 1 set | Bochu CYPCUT system |

| Main pneumatic element | matching | Japan SMC/ Taiwan AirTAC |

| Precision water chiller | 1 set | Teyuchillers |

| Dust extraction device | 1 set | Equipment matching |

| Computer | 1 PC | Taiwan professional industrial computer |

| Note: The above configuration is just as reference. The specific configuration can be customized according to customer needs. | ||

| Machine Introduction: |

| Our Advantanges: |

- Easy-to-Operate functions and excellent performance.

- World-class components.

- 24/7 online service.

- Quick and kind response for post-sales service.

- Exclusive Customization as per customer's request.

| Packing and Delivery: |

| About US: |

| Baike intelligent Technology Co., Ltd was established in 2014 and it headquartered in Wuhan, China. Over the past 10 years, we have the best R&D, production and marketing teams in the laser industry, and have successfully developed more than 500 laser products, which are exported to more than 180 countries. Our product footprints are spread across all walks of life around the world, and our product quality and services have been 100% praised. Baike is committed to providing innovative industrial laser solutions to customers around the world! Welcome to visit our factory at any time in Wuhan City, China! |

| FAQs: |

|

1.What types of jewelry can be made or repaired using a laser welder?

Answer:Laser welders are suitable for a variety of jewelry materials, including gold, silver, platinum, and some alloys. They can be used to create intricate designs, join broken pieces, and add decorative elements to rings, necklaces, earrings, bracelets, and more.

|

|

2.What safety precautions should be taken when using a laser welder for jewelry?

Answer: Safety is paramount when using a laser welder. Always wear appropriate eye protection, such as laser-safe goggles, and ensure the work area is well-ventilated to avoid inhalation of fumes. Additionally, follow all operating instructions and keep flammable materials away from the machine.

|

|

3.Can a beginner use a jewelry laser welder, or does it require specialized training?

Answer: While laser welding can be learned by beginners, it does require some technical knowledge and practice to master. It's advisable to take a training course or watch tutorial videos to understand the fundamentals of operation, safety procedures, and best practices.

|

|

4.How much maintenance does a jewelry laser welder require?

Answer: Like any high-precision equipment, a laser welder requires regular maintenance to ensure optimal performance. This includes cleaning the lens, checking the laser tube and other components for wear, and performing software updates as needed.

|

| 5.How about Warranty? Answer: We offer a one-year warranty(not include consumables) except for human damage. |